DAZLE – the design

Introduction

DAZLE, the Dark Ages 'Z' Lyman Explorer, was funded from the PPARC

Opportunity Scheme, which was set up to encourage truly innovative research,

demonstrating originality and creativity. DAZLE is being built here at the

Institute of Astronomy, University of Cambridge, UK. We collaborated with our

colleagues at the Anglo-Australian Observatory, Sydney, Australia for a large

part of the mechanical design.

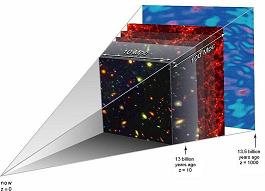

DAZLE is intended to be the first imaging instrument optimised to

detect faint emission lines between the intense lines of the OH airglow

spectrum that hinders current ground-based observations. In conjunction with

the improved image quality now demonstrated with new 6.5-10 m telescopes, DAZLE

will be the only instrument well suited to searching for early star-forming

systems located beyond the redshift range probed by current instruments for at

least the next 5 years. The predicted flux limit for detecting un-reddened

Lyman-alpha emission at redshifts of 10 corresponds to a star formation rate of

only 1 solar mass per year. The large format detector we have available in the

CIRPASS camera makes it ideal for wide field survey work.

Functional Concept

The fundamental idea of DAZLE is to use the camera from CIRPASS in

conjunction with very carefully chosen and constructed narrowband filters to

detect high-z galaxies by differential imaging of redshifted Lyman-alpha

emission at a specific wavelength, selected to be free of atmospheric emission.

The CIRPASS camera has particularly low noise, high sensitivity and good

imaging characteristics that make it especially suitable for this application.

DAZLE is intended to operate as a VLT visitor instrument, on the

Nasmyth platform of VLT UT3. Such a concept immediately requires certain system

components:

- The VLT Nasmyth focal plane needs to be collimated for input to

the CIRPASS camera.

- Extremely specialised and carefully specified filters are used

for differential imaging. The technology to construct filters suitable for the

purposes of DAZLE has only relatively recently been demonstrated.

- A filter exchange mechanism is required to swap the filters for

differential imaging.

Further constraints on the system are imposed by operational and

design features of the CIRPASS camera, and constraints imposed by ESO on

visitor instruments fitted to the VLT. The CIRPASS camera is designed to

operate viewing vertically downwards, and so cannot be mounted directly on the

VLT Nasmyth rotator to track the rotating sky image during exposures. This

means that a fold mirror must be used to turn the horizontal axis of the

Nasmyth focus vertically so it may be imaged into the camera, and the camera

rotated to track the sky by a mechanism that duplicates the action of the VLT

Nasmyth rotator, but with a vertical axis. ESO impose additional constraints on

visitor instruments at the VLT:

- Size and weight

- Vibration transmitted to the VLT structure

- Heat transfer to or from the telescope enclosure

- Earthquake survivability

- Health and safety requirements

The CIRPASS cryogenic camera is operated at approximately –190°C,

being cooled by liquid nitrogen.

A sensitivity analysis further revealed that to achieve the

required performance the complete DAZLE optical train needs to be maintained at

a low temperature (-40°C), and so a refrigerated enclosure is needed to house

the complete system on the Nasmyth platform.

Design

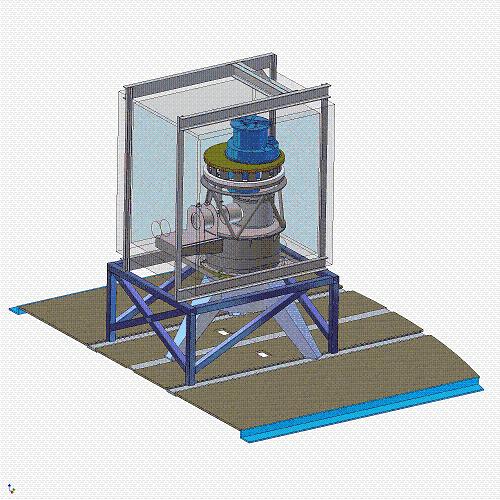

The mechanical assembly is shown in Figure 1 below. In this

design, the DAZLE instrument is housed in a refrigerated enclosure raised to

the height of the Nasmyth focus on a sub-frame.

Figure 1: DAZLE, mounted on the VLT UT3 Nasmyth platform

A collimator aligned with the Nasmyth focus collimates the input

(f/15) beam and directs it to a fold mirror beneath the CIRPASS camera. The

CIRPASS camera is supported in a structure that provides rotation capability

for tracking the sky image. A filter deployment mechanism is mounted

immediately beneath the camera, using filter wheels to swap between the

narrowband filters for differential imaging. The overall assembly is described

in the following substructures:

- Support structure

- Camera assembly

- The optical train

- Filter and mask wheel assembly

- Insulating enclosure

Support Structure

The support structure

consists of a tripod to raise the complete instrument to the height of the

Nasmyth optical axis, and a ‘saucepan’ to support the optical components of the

collimator, the fold mirror, filter and mask wheels assembly, and the CIRPASS camera.

The tripod is on the ‘warm’ side of the instrument at ambient temperature,

while the saucepan is maintained at –40oC within the refrigerated

enclosure. A thermal break is situated between the two.

Camera rotator assembly

The assembly in Figure 2 shows the components of DAZLE that

support the CIRPASS camera, enabling rotation to track the sky during an

exposure. Such rotation is an exacting requirement, and the bearing selected to

enable this needs to be exceedingly accurate. The AAO selected a suitable

bearing (originally intended for use with a radar tracker!) and conducted tests

to verify that the axial runout specification is met by this precision bearing.

At the IoA we have carried out

stability tests of the complete rotator system, to verify that it meets our

specification.The complete rotator and camera assembly is supported above the

saucepan by an open tube system providing the necessary degree of stiffness.

The camera is rotated via a high resolution control system driving a stepper

motor and a 100:1 gearbox, enabling it to track celestial objects.

Figure 2: The camera rotator assembly

The optical train

A five-element chromatic design of standard Schott glass, arranged

in two groups, is used to collimate the light from the VLT Nasmyth focus. As

the filter band-pass is extremely narrow – about 1 nanometer – an achromatic

design is unnecessary. All lens surfaces are spherical. The first two elements

act as a double-glazed window to the refrigerated enclosure. The last three

elements move together to enable the collimator to be focused.

The collimated beam is turned through 90 degrees by a fold mirror

to direct the beam towards the filter and mask wheels assembly and the downward

facing camera.

Figure 3: The DAZLE

optical train

The heart of the instrument is the pair of narrow band filters in

the collimated space. These two filters are separated by a few nanometers in

wavelength, with their central wavelengths chosen to fit in gaps between the

strong night sky OH emission. Imaging is essentially carried out in a

differential mode – images are taken through the two filters, and one image

subtracted from the other. Any object still seen in the subtracted image is a

potential Lyman alpha emission.

The light beam then enters the cryogenic camera borrowed from

CIRPASS. Again, this is a five element chromatic design, using standard Schott

glasses, and with all spherical surfaces. The detector is a state of the art

Rockwell Hawaii II, 2048x2048 Mercury-Cadmium-Tellurium device. Fine focusing

of the camera is achieved by moving the detector assembly using cryogenic

stepper motors. The camera incorporates several long pass filters to stop the

detector seeing any thermal emission.

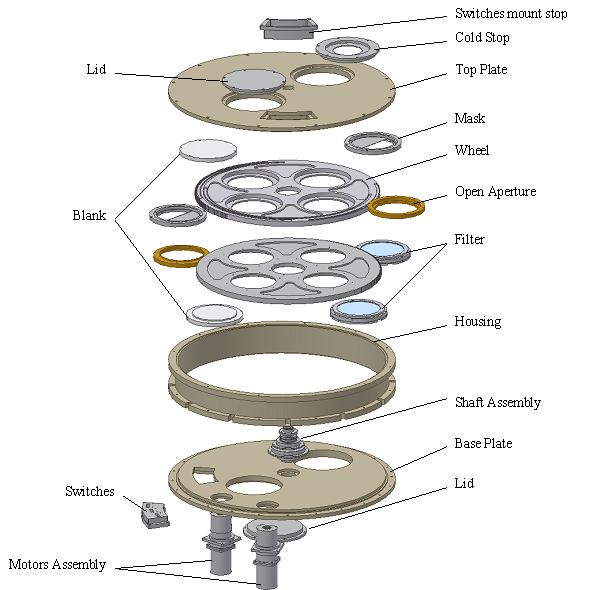

Filter and mask assembly

The wheels assembly contains two wheels, one containing the pair

of narrow band filters, the other containing masks used when focusing DAZLE. It

is mounted in the collimated beam in between the fold mirror and the camera. A

pupil image is formed close to the upper surface of the wheels assembly, and so

the system incorporates a cold stop, preventing the camera from seeing the warm

exterior outside the cold room.

Figure 4: Wheels assembly

Insulating Enclosure

The instrument is enclosed within an insulated cold room,

maintained at a system temperature of -40°C. The cold room is supported by its

own support framework and is detached from the instrument itself. Thermal seals

bridge the gap between the cold room and the instrument support. Cooling is

provided by an external refrigerator, and an evaporator inside the cold room.

Electrical, vacuum and liquid nitrogen supplies are fed through interface panels

in the enclosure walls. Our experience with CIRPASS has shown this type of cold

room is perfectly adequate to maintain the internal temperature at up to 65°C

below ambient.